Mounts for Fiberglass Antennas

Mounts for Fiberglass Antennas

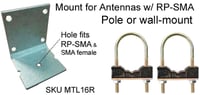

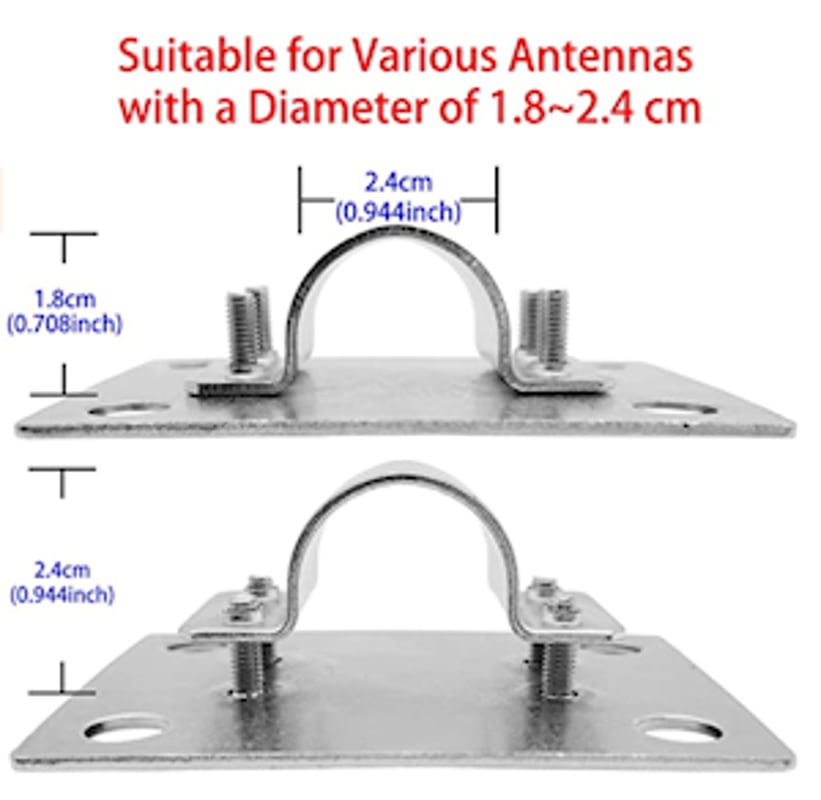

Mounting brackets including pole-mounts, wall mounts, and U-bolt kits for fiberglass antennas.

Types of Mounts for Fiberglass Antennas

Fiberglass antennas have become a mainstay in various communication scenarios due to their durable nature and efficient performance. However, their true potential is unlocked only when they are paired with the right mount. This article will explore the varied dimensions of mounts designed specifically for fiberglass antennas, emphasizing types, key features, applications, and materials composition.

-

Magnetic Mounts: These utilize strong magnets to secure the antenna on metal surfaces, making them ideal for temporary setups.

-

Bracket Mounts: Suitable for walls, structures, or vehicles, these mounts use brackets to hold the antenna in place.

-

Roof and Trunk Lip Mounts: Primarily used on vehicles, these mounts fix to the roof or the lip of the trunk without major alterations.

-

Pole Mounts: Used extensively for permanent setups, these mounts secure the antenna to a pole or mast for elevation.

-

Ground Plane Mounts: These mounts come with an integrated ground plane, enhancing the performance of the antenna, especially in environments where a natural ground plane is absent.

Key Features

-

Sturdy Grip: Given the lightweight nature of fiberglass antennas, mounts should ensure a firm grip, especially in windy conditions.

-

Weather Resistance: Mounts should be able to withstand various weather conditions, ensuring longevity and continued performance.

-

Versatility: Adjustability in terms of angle and orientation is vital for optimal signal reception or transmission.

-

Ease of Installation: Quick and hassle-free installation can save time and potential costs.

-

Non-abrasive Materials: To ensure the fiberglass antenna doesn't get scratched or damaged, mounts should have non-abrasive components.

Applications

-

Vehicle Communication: Fiberglass antennas, due to their durability and flexibility, are often used on cars, trucks, and RVs for radio communications.

-

Marine Use: Being resistant to the corrosive marine environment, fiberglass antennas are employed on boats and ships, necessitating mounts that can handle the unique challenges of the sea.

-

Ham Radio: Amateur radio enthusiasts find fiberglass antennas effective for their setups, with mounts aiding in achieving the desired orientation and height.

-

Base Stations: In stationary setups like homes or offices, fiberglass antennas coupled with the right mounts can offer excellent communication capabilities.

-

Emergency Services: Firefighters, police, and other emergency services often rely on fiberglass antennas for reliable communication, requiring mounts that can endure challenging situations.

Materials Composition

When considering the materials used in mounts for fiberglass antennas, they primarily include:

-

Stainless Steel: Known for its strength and rust-resistance, stainless steel is a common choice, especially for outdoor mounts.

-

Aluminum: A lightweight yet robust metal, aluminum is often preferred for its anti-corrosive properties and ease of manipulation.

-

High-strength Plastics: In situations requiring insulation or where weight is a concern, high-grade plastics that resist UV degradation come into play.

-

Rubber and Silicone: Used as padding or for seals, these materials prevent damage to the fiberglass antenna and ensure a watertight fit in certain applications.

To sum it up, mounts play an indispensable role in maximizing the efficiency of fiberglass antennas. From the hustle and bustle of city streets to the challenging marine environments, having the right mount ensures consistent and reliable communication. When choosing a mount, always consider the specific requirements of your setup, the environment, and the unique characteristics of fiberglass antennas to achieve the best results.