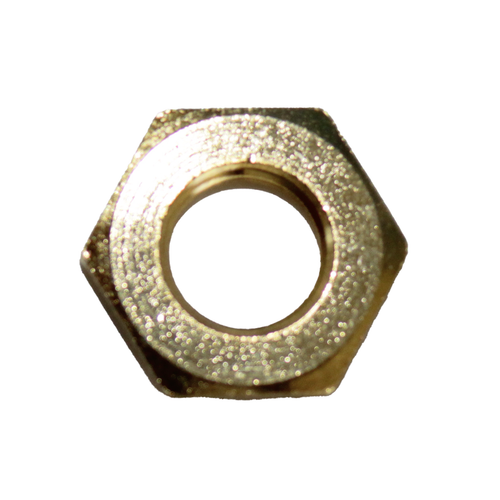

Bulkhead Nut for SMA & RP-SMA: Larger version 11mm diameter

$0.30

- SKU:

- SMAnut11mm

- Availability:

- In stock

- Weight:

- 0.01 LBS

Brand:

Data Alliance

Bulkhead Nut for RP-SMA & SMA: 11mm from flat to flat

- Larger nut version for RP-SMA-female and SMA female connector:

- This hex nut for SMA and RP-SMA measures 11mm across the opposite flats, whereas the standard hex nut for SMA / RPSMA is 5/16 inch (0.3125 inch / 7.9 mm) across opposite flats.

- The inside diameter is 6mm, to clear the threads on the female connector.

- Bulkhead nut & washer to mount connector on enclosure or PCB. SMA and RP-SMA use the same hex nut and washer set.

The purposes of the bulkhead on an SMA-female or RP-SMA-female are to:

- Enable the connector to serve as a mounting device, such as to mount the cable to an enclosure, case or Printed Circuit Board (PCD).

- Weatherproofing: Seal the hole where the connector is mounted, by placing an O-ring between the wall of the enclosure and the O-ring.

The bulkhead does not in any way interfere with the ability of a female connector to properly "mate" with a male connector: In other words, a female connector with a bulkhead mates/connects exactly as well as a female connector without a bulkhead.

RoHS and REACH compliant: All of our antenna cables and RF adapters are from of heavy metals and compliant with RoHS and REACH.

RELATED PRODUCT OPTIONS

- Rubber waterproof O-ring seal can be purchased as a standalone item.

Gold-Plated Brass & Nickel-Plated Brass Options

- All of our Brass options are gold-plated. Gold-plating is better in appearance and more expensive than nickel-plated one.

- For indoor applications: Gold-plated brass alloy is the best option, because gold-plating is more attractive.

- For outdoor applications: Nickel-plated brass is the best option to weatherproof SMA and RP-SMA antenna connectors (read more below).

Rust Proofing and Corrosion-Protection: Best Options Among Nickel, Gold-Plated Brass & Brass Alloys:

- Nickel-plated brass is the most corrosion-resistant option:

- Nickel does not decompose as it oxidizes, but forms a layer of nickel-oxide that prevents further oxidation from occurring.

- Nickel-plating is achieved by electro-plating the brass nuts and washers with a thin layer of nickel.

- The result is nuts & washers that are highly resistant to rust /oxidation and verdigris (those green spots that show up on old brass)

- Rust Proofing and Corrosion-Protection is Achieved in our 100% Brass w/Gold Plate Version By:

- Keeping zinc content below 15%

- Adding in other metals to the alloy such as arsenic, phosphorus, antimony, and tin

With Zinc content below 15%, brass alloys can be rust-proof as long as:

- Aeration is kept at a minimum.

- The brass is kept away from oxidizing materials that include cyanides, ammonia, dichromates, and nitric acid.

- Reactive materials such as acetylene, silver salts, mercury, hydrogen sulphide, and sulphur are not present

- The components are kept away from salt, chemicals in the air, tap water, and rainwater.