Antennas, Antenna Cables, Wireless Products: Technical Articles

SMP Connectors & Cable Assemblies — a Practical Guide

Table of Contents

- SMP cable assemblies are used for:

- What is SMP?

- Mechanical variants you’ll encounter

- Coax types commonly paired with SMP

- Typical applications

- Durability & service life

- SMP cable assemblies — what “good” looks like

- Design & build notes (to avoid headaches)

- Test & acceptance checklist

- Pros & cons vs. alternatives

- Quick selection guide

- In summary

- FAQs

SMP cable assemblies are used for:

- High-durability, as needed in high-vibration environments: Examples: Vehicles and heavy machinery. In these situations, they are often for GPS devices or a GPS module embedded in a PCBA or PCB stack.

- High-frequency connections (often in the 6–18 GHz range, and even up to 40 GHz for some SMP variants.

What is SMP?

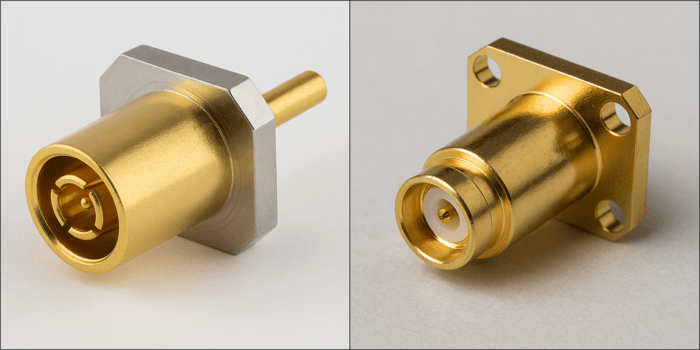

SMP (a.k.a. GPO) is a miniature, push-on RF/microwave connector system designed for high density and blind-mate use. It’s common in compact modules where SMA/SMB are too large or can’t be threaded. SMP uses a gendered plug/jack with spring fingers and a detent to hold engagement.

SMP is part of a family:

SMP (GPO): most common; typical ratings to 26.5–40 GHz (depends on grade).

SMPM (GPPO): smaller; often 40–65 GHz.

SMPS: ultra-mini; specialized, up to ~90 GHz in precision versions.

(This article focuses on SMP/GPO.)

Mechanical variants you’ll encounter

Detent style (retention force):

Full-detent: highest retention; best for shock/vibration; hardest to unplug.

Limited-detent: balance of hold vs. serviceability.

Smooth-bore (no detent): easiest blind-mate; lowest retention (use in captive/bullet applications).

“Bullet” adapters (male–male): enable board-to-board, board-to-chassis, or blind-mate between two SMP jacks. Standard effective lengths let you tune stack-height and float.

Float/guide hardware: many housings allow radial and axial misalignment so modules can mate without precise fixturing.

Launch styles: end-launch and edge-launch PCB jacks; vertical and right-angle; cabled jacks for pigtails; flange/panel versions.

Electrical performance (rule-of-thumb ranges)

Frequency: commercial SMP parts are commonly specified to 26.5 GHz; precision grades and short-transition designs reach ~40 GHz.

Return loss / VSWR: good assemblies often achieve ≥ 15–20 dB RL (≈ VSWR ≤ 1.43:1…1.22:1) over their intended band; premium parts can be better.

Insertion loss: dominated by cable choice and length. The connector adds a small fraction of a dB; short assemblies (e.g., 4 in / 100 mm) are typically very low-loss below 18–26 GHz.

Power handling: modest compared with threaded families; de-rates with frequency and altitude. Think low tens of watts CW at lower GHz on suitable cable—use data sheets for exact curves.

Coax types commonly paired with SMP

SMP is usually mated with semi-rigid or low-loss micro-coax:

Semi-rigid:

0.047″ (RG-178-size inner, copper or CuNi outer): tiny, flexible only when formed.

0.085″ (RG-405) and 0.141″ (RG-402): excellent stability and shielding; you pre-form bends.

Conformable (hand-formable): tinned copper braid/foil jackets that hold a bend, easier than true semi-rigid, slightly higher loss.

Flexible microwave cables: ePTFE or low-density PTFE dielectrics, double-shield braid/foil; chosen when frequent motion or vibration is expected.

Which to pick?

For highest frequency & phase stability: 0.085″ or 0.141″ semi-rigid → SMP.

For service loops / frequent handling: quality flexible microwave cable with SMP crimp/solder jacks.

For tight routing in modules: 0.047″ semi-rigid or micro-flex.

Typical applications

Aerospace/defense RF modules: T/R modules, phased arrays, EW/ radar LRUs—blind-mate trays with bullets are standard.

Satcom & microwave backplanes: dense interconnect where threading is impractical.

Test fixtures & load boards: quick mate/demate, high frequency probing inside enclosures.

5G/mmWave prototypes & compact radios: where board-to-board RF jumpers must be small and repeatable.

Durability & service life

Mating cycles: commonly 100–500 (varies by finish/detent). Smooth-bore/bullet interfaces tolerate more blind-mate cycles; full-detent retains best but wears faster if over-used.

Materials/finish: bodies in stainless or brass; contacts often beryllium-copper with gold. Keep clean—contamination quickly degrades RL and wear.

Vibration/shock: SMP excels with full-detent or captured bullets in floating housings. For mobile platforms, avoid smooth-bore unless mechanically retained.

Environmental: most variants support –55 °C…+125 °C; check altitude/power for corona limits at high GHz.

SMP cable assemblies — what “good” looks like

For a short (e.g., 4″) assembly:

Return loss (S11/S22): aim ≥ 20 dB across your working band; ≥ 15 dB as a minimum acceptance in many labs. S11 ≈ S22 indicates symmetric build quality.

Insertion loss (S21): small and smooth, rising with frequency; no unexpected ripples or deep notches.

Repeatability: disconnect/reconnect should not shift RL/S21 more than a dB or two at band edges. If it does, check wear/contamination or detent choice.

Design & build notes (to avoid headaches)

Choose detent intentionally.

Lab fixtures: limited-detent for serviceability.

Fielded modules: full-detent + float hardware; use bullets for blind-mate.

Bullet length & float.

Pick bullet length to match your stack height; allow axial float and ±° radial misalignment per the connector’s spec.Cable selection = performance.

Higher diameter → lower loss & better phase stability; trade against bend radius and weight.Termination quality rules return loss.

Control pin depth, dielectric trim, solder/braid prep, and strain relief. Minor geometry errors show up as S11/S22 asymmetry.Routing.

Respect minimum bend radius (typically 5–10× OD for flex; as formed for semi-rigid). Avoid tight bends at the connector heel—use boots or brackets.Cleanliness.

Dust, skin oils, or plating debris raise VSWR. Use lint-free swabs and compatible solvents; cap when not in use.No torque!

SMP is push-on—design mechanical retention if you need it; don’t rely on the RF joint to carry cable loads.

Test & acceptance checklist

Test & acceptance checklist

VNA sweep (S11/S22/S21) over the target band; verify both ends meet RL target and traces are smooth.

SWR spot markers at critical bands (GPS, cellular, Wi-Fi, satcom, radar).

Flex test (if applicable): move the cable through expected motion while watching S-parameters for stability.

Mating wear: after N cycles, re-verify RL; inspect springs/fingers for plating wear or splay.

Pros & cons vs. alternatives

Pros

Very compact, high-density, blind-mate capable

High frequency support (well into mmWave in smaller variants)

Supports floating/misalignment with bullets

Cons

Lower power and PIM performance than larger threaded families

Wear and contamination more impactful; finite mating life

No threaded retention—needs proper detent choice and mechanical design

Quick selection guide

Band: up to 18/26.5 GHz → SMP; 40–65 GHz → consider SMPM.

Environment: vibration → full-detent and bullets with float; lab → limited-detent.

Cable: static/precision → semi-rigid 0.085/0.141; service loop/flex → low-loss flexible; ultra-tight space → 0.047″.

Spec targets: design for ≥ 20 dB RL, smooth S21, and adequate power de-rate margin.

Maintainability: cap, clean, and track mating cycles.

Typical Performance Benchmarks for SMP Cable Assemblies

A well-performing SMP cable assembly will show very good return loss on both S11 and S22 across the intended frequency band. Here are some typical benchmarks and acceptable values for high-quality SMP-F cables:

- Return Loss (S11, S22): Aim for at least 15 dB return loss or better across the operating band. In high-performance applications, ≥20 dB is often expected, especially at lower GHz frequencies (20 dB RL corresponds to ~1% reflected power). Many SMP cable connectors can achieve 20–26 dB return loss in practice over a broad range. For example, a certain SMP termination is rated for ~26 dB up to 8 GHz and ~20 dB up to 18 GHz, and a straight SMP cable connector is specified at ≥23 dB up to 20 GHz. These numbers indicate an excellent match (VSWR on the order of 1.1–1.2:1). An assembly hitting around 20 dB RL or above is considered excellent. Around 15 dB (VSWR ~1.43:1) is generally acceptable for many high-frequency systems, but it might be the lower limit for stringent applications. If return loss drops to ~10 dB or worse (≈ 2:1 VSWR), that’s usually a red flag – it means ~10% or more of the power is reflected, pointing to a sub-par connector or a problem in the assembly.

- Symmetry: A good SMP cable assembly should have S11 and S22 that nearly overlap when plotted. In other words, both ends should perform comparably. As noted, any major deviation means one end is not meeting the same benchmark as the other. For a quality cable, you might see both S11 and S22 stay better than –20 dB through, say, 6 GHz, gradually reducing to –15 dB at the top frequency. If one end only manages –15 dB at mid-band while the other is –25 dB, the assembly is not uniformly performing. High-end test cables (including those with SMP or similar connectors) are often characterized by very symmetric S11/S22 curves, indicating uniform construction.

- Insertion Loss (FYI): Although the question focuses on S11/S22, it’s worth noting that a 4″ cable will have very low insertion loss (S21) – perhaps on the order of a few tenths of a dB at high GHz frequencies. This means most signal loss is not due to length but any mismatch at the ends. That puts even more emphasis on return loss: with such a short cable, a poor return loss could actually be the dominant source of signal issue (since little is lost in the cable itself). Thus, meeting the return loss benchmarks is critical for the assembly to be considered “well-performing.”

In summary

A well-performing 4″ SMP cable assembly in high-frequency testing would typically show on the order of 20 dB or better return loss on both S11 and S22 across the band of interest, with very little difference between the two ends. Practically, values like “≥20 dB up to 18 GHz” or “≥15 dB up to 40 GHz” might be seen on spec sheets, and technicians often use ~15 dB as a cutoff for acceptable VSWR in many applications. Hitting these marks ensures that reflections are minimal, connectors are well matched, and the cable assembly can be confidently used in demanding RF tests without introducing significant measurement errors or losses.

FAQs

What is an SMP connector and where is it used?

SMP (also called GPO) is a miniature push-on RF/microwave connector system designed for high-density and blind-mate applications. It is commonly used in aerospace, defense, satellite communications, radar systems, and compact RF modules where SMA or SMB connectors are too large or impractical.

What frequency range do SMP cable assemblies support?

Commercial SMP connectors typically support up to 26.5 GHz, with precision grades and short-transition designs reaching 40 GHz. Variants like SMPM (GPPO) extend up to 65 GHz, while SMPS can achieve frequencies near 90 GHz.

What mechanical retention styles are available for SMP connectors?

SMP connectors come in three detent styles:

- Full-detent: Highest retention, best for vibration and shock.

- Limited-detent: Balanced retention and serviceability.

- Smooth-bore: Easy blind-mate, lowest retention (used in bullet/captive applications).

Which coaxial cables are typically used with SMP assemblies?

SMP connectors are often paired with:

- Semi-rigid coax (0.047″, 0.085″, 0.141″) for high stability and low loss.

- Conformable coax for easier routing with slightly higher loss.

- Flexible microwave cables (ePTFE, PTFE dielectric) when vibration resistance and frequent motion are required.

What are typical performance benchmarks for SMP cable assemblies?

A high-quality SMP assembly should achieve:

- Return Loss (S11/S22): ≥ 20 dB across most of the band; ≥ 15 dB minimum acceptable.

- Insertion Loss (S21): Very low for short lengths (fractions of a dB at high GHz).

- Symmetry: Both ends (S11 and S22) should perform nearly identically.

How durable are SMP connectors in high-vibration environments?

With the right detent style (typically full-detent) and bullet adapters in floating housings, SMP connectors perform well in vehicles, aircraft, and heavy machinery. They typically support 100–500 mating cycles, depending on finish and retention style.

What are common applications of SMP cable assemblies?

SMP is widely used in:

- Aerospace & defense RF modules (phased arrays, EW systems, radar).

- Satellite communications backplanes with dense, blind-mate interconnects.

- Test fixtures & load boards where quick connect/disconnect is required.

- 5G and mmWave prototypes for compact, high-frequency RF jumpers.

How do SMP connectors compare with alternatives like SMA or SMPM?

- Advantages: Compact size, blind-mate capability, support for high frequencies, and tolerance for misalignment with bullets.

- Limitations: Lower power handling and passive intermodulation (PIM) performance compared to threaded families like SMA; shorter mating life.

For frequencies above 40 GHz, SMPM or SMPS may be better suited.