Antennas, Antenna Cables, Wireless Products: Technical Articles

Heat Shrink Tubing for Antenna Cables: Types, Tips, Sizing

Table of Contents

- Adhesive-Lined Heat Shrink Tubing: Recommended

- Standard (Non-Lined) Heat Shrink Tubing: Limited Use

- Practical Tip:

- Summary Conclusion

- Recommended Heat Shrink Tubing Sizes for Coaxial Antenna Cables

- Tips for Application

-

- Materials Used in Heat Shrink Tubing for Antenna Cables

- Most Common Type for Antenna Cable Installations

- Why Polyolefin Is Ideal for Antenna Cables

- Notes

- FAQs

For antenna cables made with LMR-100, LMR-200 and LMR-400 coaxial cable, adhesive-lined heat shrink tubing is generally better than standard (non-lined) tubing. Here's why:

Adhesive-Lined Heat Shrink Tubing: Recommended

Advantages:

Moisture Seal: The internal adhesive melts and flows during shrinking, creating a watertight seal around both the connector and the cable jacket.

Strain Relief: Provides better mechanical support at the junction between the cable and connector, minimizing risk of damage from movement or vibration.

Environmental Protection: Especially useful for outdoor antenna cables, as it blocks out dust, dirt, and UV exposure.

Longer-Term Durability: It resists thermal cycling, ensuring the seal holds in both hot and cold environments.

Best Use Case:

Outdoor or semi-exposed environments

Where water ingress or corrosion is a concern (e.g., rooftops, towers, marine setups)

Standard (Non-Lined) Heat Shrink Tubing: Limited Use

Advantages:

Easier to apply and slightly cheaper

Works fine in indoor or controlled environments

Can be sufficient if you use other sealing methods (like tape or weatherproof boots)

Disadvantages:

Does not provide a moisture barrier

Can allow air and moisture to seep in, leading to oxidation or RF leakage over time

Practical Tip:

Choose a tubing with:

3:1 shrink ratio to ensure tight fit around the cable and connector

UV resistance if used outdoors

Sufficient length to cover part of the connector and extend onto the cable jacket for secure adhesion

Summary Conclusion

Adhesive-lined heat shrink tubing is the superior choice for sealing and protecting LMR-200/400 cables with SMA and Type N connectors, particularly in outdoor or mission-critical RF applications.

Recommended Heat Shrink Tubing Sizes for Coaxial Antenna Cables

Coax Cable Type | Nominal Cable Diameter | Recommended Tubing (Before Shrink) | Recommended Tubing (After Shrink) | Shrink Ratio | Notes |

LMR-100 | 0.10 in (2.5 mm) | 3/16 in (4.8 mm) | 0.0625 in (1.6 mm) | 3:1 | Light-duty pigtails, GPS leads |

LMR-195 / RG58 | 0.195 in (4.95 mm) | 1/4 in (6.4 mm) | 0.08 in (2 mm) | 3:1 | Wi-Fi / LTE cables |

LMR-200 | 0.195 in (4.95 mm) | 1/4 in (6.4 mm) | 0.08 in (2 mm) | 3:1 | Slightly more rugged than LMR-195 |

RG-6 | 0.27 in (6.9 mm) | 3/8 in (9.5 mm) | 0.12 in (3 mm) | 3:1 | Often used for TV antennas |

LMR-240 | 0.24 in (6.1 mm) | 3/8 in (9.5 mm) | 0.12 in (3 mm) | 3:1 | Moderate-power RF uses |

LMR-400 | 0.405 in (10.3 mm) | 1/2 in (12.7 mm) or 3/4 in (19 mm) | 0.17 in (4.5 mm) to 0.25 in (6.4 mm) | 3:1 | Heavy-duty outdoor cable |

LMR-600 | 0.59 in (15 mm) | 3/4 in (19 mm) to 1 in (25 mm) | 0.25 in (6.4 mm) to 0.33 in (8.5 mm) | 3:1 | High-power runs, long lengths |

RG-213 / RG-214 | 0.405 in (10.3 mm) | 1/2 in (12.7 mm) or 3/4 in (19 mm) | 0.17 in (4.5 mm) to 0.25 in (6.4 mm) | 3:1 | Shielded mil-spec coax |

RG-8X (Mini-8) | 0.242 in (6.15 mm) | 3/8 in (9.5 mm) | 0.12 in (3 mm) | 3:1 | HF radio and marine use |

Tips for Application

Adhesive-lined tubing ensures a weatherproof, tight bond with both the connector and cable jacket.

Select a tubing that is just large enough to slide over the connector but will shrink tightly around the cable.

Use a heat gun, not an open flame, to activate the adhesive and ensure even shrinkage.

For long-term outdoor use, choose tubing that is UV-stabilized and rated for -55°C to 125°C.

Materials Used in Heat Shrink Tubing for Antenna Cables

The material composition of heat shrink tubing for antenna cables—especially when used for outdoor RF connectors like SMA, N-Type, RP-SMA, TNC, and LMR-series coax—is critical for ensuring weather resistance, UV durability, and electrical insulation. Here's a breakdown of the most common materials used:

Material | Typical Use | Key Properties | Applications |

Polyolefin (cross-linked) | Most common heat shrink tubing | - Excellent insulation | General-purpose, indoor/outdoor cable sealing |

Adhesive (hot melt glue) | Inner lining in dual-wall tubing | - Seals out moisture and dust | Outdoor weatherproofing, marine, telecom |

Fluoropolymer (e.g., PTFE, FEP, PVDF) | High-performance tubing | - High-temp (up to 200–250°C) | Aerospace, military, extreme weather |

Elastomeric polyolefin or Neoprene | Flexible and oil-resistant use | - Rubber-like stretchability | Strain relief for high-flex installations |

Silicone Elastomer | High-flex, high-temp settings | - Very flexible | Special RF/microwave use (less common) |

Most Common Type for Antenna Cable Installations

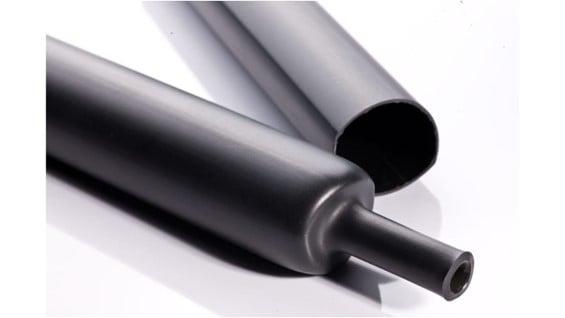

Dual-Wall Adhesive-Lined Polyolefin Tubing

This is the go-to tubing for outdoor antenna connectors due to:

Outer Layer: Cross-linked polyolefin

Shrinks uniformly

Resists UV, water, and abrasion

Inner Layer: Thermoplastic adhesive (hot melt glue)

Flows when heated and seals tightly

Bonds to connector knurling and cable jacket

Typical shrink ratio: 3:1 or 4:1

Temperature rating: -55°C to +125°C

Dielectric strength: ~15–25 kV/mm

Adhesive melt point: 80–110°C

Why Polyolefin Is Ideal for Antenna Cables

RF-Safe: Does not interfere with signal

Environmental Durability: Resistant to UV, rain, snow, and ozone

Mechanical Protection: Protects against cable flex and pull-out

Chemical Resistance: Handles fuels, oils, and cleaning solvents

Notes

Use UV-resistant tubing if cable will be exposed to sunlight continuously.

For marine or desert environments, choose tubing labeled MIL-DTL-23053/4 or similar military-grade spec.

FAQs

Why should I use adhesive-lined heat shrink tubing instead of standard tubing for antenna cables?

Adhesive-lined tubing provides a watertight seal, stronger strain relief, and better protection against UV, dirt, and temperature changes. Standard tubing may be cheaper and easier to apply but lacks moisture protection, making it unsuitable for outdoor or long-term RF installations.

When is standard (non-lined) heat shrink tubing sufficient?

Standard tubing can be used in indoor or controlled environments where cables are not exposed to water, dust, or sunlight. It may also be acceptable if additional sealing methods, such as tape or weatherproof boots, are used.

What shrink ratio is recommended for heat shrink tubing on coaxial antenna cables?

A 3:1 shrink ratio is recommended. This ensures the tubing will shrink tightly around both the connector and cable jacket, creating a secure fit and proper environmental seal.

Which size heat shrink tubing should I use for LMR-100, LMR-200, and LMR-400 cables?

- LMR-100 (0.10 in / 2.5 mm): 3/16 in before shrink → 0.0625 in after shrink

- LMR-200 (0.195 in / 4.95 mm): 1/4 in before shrink → 0.08 in after shrink

- LMR-400 (0.405 in / 10.3 mm): 1/2 in or 3/4 in before shrink → 0.17–0.25 in after shrink

What material is best for outdoor antenna heat shrink tubing?

Dual-wall adhesive-lined polyolefin is the most common and reliable choice. Its outer layer resists UV, abrasion, and weather, while the inner adhesive layer bonds tightly to both the connector and cable jacket, creating a long-lasting waterproof seal.

How do I properly apply adhesive-lined heat shrink tubing?

- Choose tubing just large enough to slide over the connector.

- Position it to cover part of the connector and extend onto the cable jacket.

- Use a heat gun (not an open flame) to evenly shrink the tubing.

- Allow the adhesive to flow and bond for a tight, weatherproof seal.

Can heat shrink tubing affect RF performance?

No. Polyolefin-based adhesive-lined tubing is RF-safe and does not interfere with signal performance. Instead, it protects the connection from environmental and mechanical damage that could otherwise degrade performance.

What temperature and environmental ratings should I look for?

For long-term outdoor use, choose tubing rated for -55°C to +125°C, UV-stabilized for sunlight exposure, and compliant with MIL-DTL-23053/4 or similar specifications if used in harsh marine or desert environments.