Antennas, Antenna Cables, Wireless Products: Technical Articles

Future Trends & Innovations in Antenna Cables for IoT

Table of Contents

- Introduction. Future Trends & Innovations in Antenna Cables.

- Higher Frequencies Are Driving Lower-Loss Cable Design

- Micro-Coax Miniaturization for Compact IoT Devices

- Low-PIM Antenna Cables for Spectrum-Dense Environments

- Advanced Materials and Dielectrics

- Ruggedization for Industrial and Outdoor IoT

- High-Frequency Stability and Impedance Control

- Application-Specific and Custom Antenna Cable Assemblies

- The Evolving Role of Antenna Cables in IoT Architectures

- Conclusion

- FAQs

Introduction. Future Trends & Innovations in Antenna Cables.

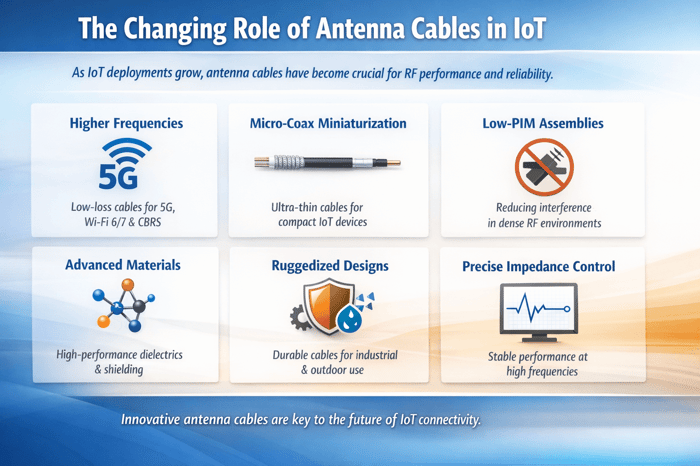

As Internet of Things (IoT) deployments expand in scale and complexity, antenna cables are becoming increasingly critical to overall system performance. Once treated as passive, interchangeable components, antenna cables are now recognized as key RF links that directly influence signal integrity, reliability, and long-term scalability.

Several converging forces are driving this shift: wireless technologies operating at higher frequencies, aggressive device miniaturization, denser RF environments, and deployment in harsher physical conditions. Together, these trends are pushing antenna cable design well beyond traditional coaxial assemblies and into a new generation of highly engineered RF interconnects.

This article explores the future trends shaping antenna cable design and selection for IoT applications, including advanced materials, micro-coax miniaturization, low-PIM assemblies, high-frequency performance demands, and ruggedization for industrial and outdoor environments.

Higher Frequencies Are Driving Lower-Loss Cable Design

Emerging wireless standards—such as 5G sub-6 GHz, CBRS, private LTE, Wi-Fi 6/6E, and Wi-Fi 7—operate at significantly higher frequencies than earlier IoT technologies. At these frequencies, signal attenuation in coaxial cables increases rapidly due to skin effect, dielectric losses, and impedance discontinuities.

As a result, next-generation antenna cables increasingly emphasize:

Lower-loss dielectric materials to reduce energy dissipation

Improved conductor surface quality, including smoother copper and plated conductors

Tighter impedance control to minimize reflections

Enhanced shielding effectiveness to suppress noise and leakage

At higher frequencies, even short antenna cable runs can meaningfully reduce link margin. This makes cable selection a system-level design decision, particularly for IoT gateways, access points, and edge devices that aggregate multiple radios or serve large device populations.

Micro-Coax Miniaturization for Compact IoT Devices

IoT hardware continues to shrink as designers integrate radios, processors, sensors, and power systems into increasingly compact enclosures. This trend has driven strong demand for ultra-thin, flexible micro-coax antenna cables that can route cleanly through tight mechanical spaces without compromising RF performance.

Key miniaturization trends include:

Expanded use of 1.13 mm, 1.32 mm, and 1.37 mm micro-coax

Widespread adoption of small board-level RF connectors such as U.FL, MHF4, and MHF5

Improved shielding techniques that maintain isolation at reduced diameters

Miniaturized antenna cables must strike a careful balance between electrical stability, mechanical durability, and flexibility. As cable diameters decrease, tolerance to bending, vibration, and manufacturing variation also decreases—making material selection and assembly quality increasingly important.

Low-PIM Antenna Cables for Spectrum-Dense Environments

As IoT systems increasingly coexist with cellular infrastructure, Wi-Fi networks, and private wireless systems, Passive Intermodulation (PIM) has emerged as a growing concern. PIM occurs when non-linear junctions in passive components generate unwanted interference products that fall within active receive bands.

Low-PIM antenna cable trends focus on:

Optimized conductor alloys that reduce non-linear behavior

Precision connector interfaces with consistent contact pressure

Improved termination and assembly processes

More rigorous RF and PIM testing at the assembly level

Low-PIM cable assemblies are especially important for multi-radio IoT gateways, distributed antenna systems (DAS), and private LTE/5G deployments, where multiple transmitters operate in close proximity. As spectrum becomes more crowded, controlling self-generated interference becomes essential to maintaining receiver sensitivity.

Advanced Materials and Dielectrics

Material innovation is one of the most significant drivers of antenna cable evolution. Traditional solid polyethylene dielectrics and PVC jackets are increasingly supplemented—or replaced—by materials engineered for higher frequency stability, lower loss, and improved environmental resilience.

Notable advancements include:

Foamed and expanded dielectrics that reduce dielectric constant and attenuation

PTFE and fluoropolymer materials for stable performance across wide frequency and temperature ranges

Jacket materials with enhanced UV resistance, chemical resistance, and abrasion tolerance

Compliance with modern environmental and safety regulations

These materials allow antenna cables to maintain consistent electrical characteristics across temperature extremes and long service lifetimes, making them suitable for industrial, outdoor, and mission-critical IoT deployments.

Ruggedization for Industrial and Outdoor IoT

IoT is rapidly expanding into environments that are far more demanding than traditional indoor consumer applications. Manufacturing facilities, energy infrastructure, transportation systems, agriculture, and smart cities all expose antenna cables to mechanical stress and environmental hazards.

Ruggedized antenna cable trends include:

Reinforced outer jackets for abrasion resistance

Enhanced strain relief and overmolding at connector interfaces

Resistance to moisture, oils, fuels, and corrosive substances

Improved vibration tolerance and flex-life performance

Rugged cable assemblies reduce field failures, service calls, and unplanned downtime—critical factors when IoT devices are deployed at scale or in locations that are difficult to access.

High-Frequency Stability and Impedance Control

As operating frequencies increase, antenna cables must maintain stable impedance and predictable electrical behavior across their entire length. Small variations in geometry, dielectric consistency, or connector interfaces can introduce reflections that degrade system performance.

Future antenna cable designs increasingly prioritize:

Consistent impedance across bends and flex points

Improved concentricity between conductors

Reduced sensitivity to mechanical stress

Repeatable performance across production batches

High-frequency stability is particularly important in certified wireless systems, where antenna cable variability can impact regulatory compliance and system repeatability.

Application-Specific and Custom Antenna Cable Assemblies

As IoT use cases diversify, antenna cable selection is shifting away from generic, off-the-shelf solutions toward application-optimized assemblies designed for specific electrical and mechanical requirements.

Key design considerations include:

Exact cable length optimization to minimize attenuation

Connector orientation and expected mating cycles

Environmental sealing and ingress protection needs

Regulatory and certification constraints

Custom antenna cable assemblies allow engineers to eliminate compromises, improve RF performance, and ensure consistency across product families and production runs.

The Evolving Role of Antenna Cables in IoT Architectures

Despite increasing integration of radios and antennas, antenna cables remain essential in many IoT architectures. They enable flexible antenna placement, modular designs, and adaptation to diverse deployment scenarios.

Looking ahead, antenna cables will increasingly be expected to:

Support broader frequency ranges

Maintain performance in dense RF environments

Withstand harsh mechanical and environmental conditions

Integrate seamlessly with compact, highly integrated devices

In this context, antenna cables are no longer passive accessories—they are engineered RF components that directly influence system success.

Conclusion

The future of antenna cables is shaped by higher frequencies, compact device designs, denser RF environments, and harsher operating conditions. Advances in materials, micro-coax construction, low-PIM design, high-frequency stability, and ruggedization are transforming antenna cables into critical system elements for modern IoT deployments.

By understanding these trends, IoT designers, engineers, and integrators can make informed antenna cable selections that support performance, reliability, regulatory compliance, and long-term scalability in next-generation wireless systems.

FAQs

What new materials are shaping the future of IoT antenna cables?

Advanced low-loss dielectrics, improved copper alloys, silver-plated conductors, and high-performance jacket materials are reducing attenuation while improving durability in harsh IoT environments.

How will antenna cable design evolve for 5G, LPWAN, and future IoT networks?

Future designs will prioritize lower loss at higher frequencies, tighter impedance control, and better shielding to support 5G, NB-IoT, LTE-M, LoRaWAN, and emerging sub-GHz and mmWave applications.

Why is cable loss becoming more critical in modern IoT deployments?

As IoT devices move to smaller form factors and higher frequencies, even short cable runs can significantly impact link budgets, making low-loss cable selection increasingly important.

What role will integrated and pre-terminated antenna cables play in IoT systems?

Pre-terminated and integrated cable assemblies reduce installation errors, improve RF repeatability, and simplify large-scale IoT deployments by ensuring consistent performance.

How are antenna cables being adapted for harsh industrial and outdoor IoT environments?

Innovations include UV-resistant jackets, improved moisture barriers, higher flex-life designs, and enhanced EMI shielding to ensure long-term reliability in industrial, vehicular, and outdoor IoT applications.

Will antenna cables change as IoT devices become more compact?

Yes. Thinner, lighter, and more flexible coaxial cables are being developed to support compact device designs while maintaining electrical performance and mechanical robustness.