Antennas, Antenna Cables, Wireless Products: Technical Articles

Bend Radius of LMR-100, LMR-200, LMR-400 Coaxial Cable Types

Table of Contents

Minimum Bend Radiuses. Specifications and Installation Considerations

The bend radius of a coaxial cable is a critical mechanical and electrical specification that defines the minimum radius a cable can be bent without causing physical damage or degrading signal performance. Exceeding the recommended bend radius can lead to subtle or catastrophic failures, including impedance mismatch, increased attenuation, shielding degradation, and shortened cable lifespan.

For RF applications such as IoT devices, cellular antennas, GPS systems, WiFi networks, and other wireless communication systems, understanding and respecting coaxial cable bend radius specifications is essential for reliable long-term performance.

This article focuses specifically on the bend radius of LMR-100, LMR-200, and LMR-400 coaxial cable types, three of the most commonly used low-loss RF coaxial cables in antenna and wireless installations.

Overview of LMR Coaxial Cable Types

LMR® cables are widely used due to their low attenuation, consistent impedance, and durable construction. As cable diameter increases, signal loss generally decreases—but flexibility is reduced. This makes bend radius an important trade-off when selecting the appropriate cable type.

The most common LMR cable types include:

- LMR-100 – ultra-small, highly flexible

- LMR-200 – moderate size with improved signal performance

- LMR-400 – large, low-loss cable designed for longer runs

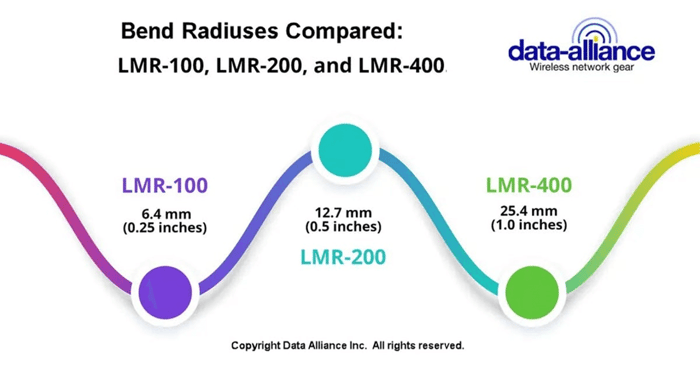

The bend radius of a coaxial cable refers to the minimum radius a cable can be bent without damaging it or degrading its performance. The minimum bend radiuses for these cables are as follows:

- LMR-100: This is a smaller diameter cable and has a minimum bend radius of 0.25 inches (6.4 mm). This allows for relatively tight bends compared to thicker coaxial cables.

- LMR-200: This cable is twice the thickness of LMR100, and has a minimum bend radius of 0.5 inches (12.7 mm). It offers a good balance between flexibility and low signal loss.

- LMR-400: Having twice the diameter of LMR-200 and quadruple the diameter of LMR-100, it is a significantly more rigid cable. LMR-400 has a minimum bend radius of 1 inch (25.4 mm) when bending in a single plane. When bending in multiple planes, a larger radius may be required to avoid damaging the cable.

Minimum Bend Radius of LMR-100, LMR-200, and LMR-400

LMR-100 Bend Radius

LMR-100 is a small-diameter coaxial cable commonly used in compact RF devices and tight installation spaces.

- Minimum bend radius:0.25 inches (6.4 mm)

- Key advantage: High flexibility

- Typical applications: IoT devices, embedded RF modules, short antenna pigtails

Because of its small size, LMR-100 allows for relatively tight bends compared to thicker coaxial cables. However, even with its flexibility, repeated sharp bends should be avoided to prevent long-term fatigue.

LMR-200 Bend Radius

LMR-200 offers a balance between flexibility and signal performance.

- Minimum bend radius:0.5 inches (12.7 mm)

- Diameter: Approximately twice that of LMR-100

- Typical applications: Cellular antennas, GPS systems, WiFi access points

LMR-200 provides lower attenuation than LMR-100 while remaining flexible enough for most indoor and outdoor installations. It is a popular choice when cable routing involves moderate bends but performance requirements are higher.

LMR-400 Bend Radius

LMR-400 is a significantly thicker and more rigid coaxial cable designed for low-loss, longer cable runs.

- Minimum bend radius (single plane):1 inch (25.4 mm)

- Diameter: Twice that of LMR-200 and approximately four times that of LMR-100

- Multiple-plane bends: Larger radius required

Due to its stiffness, LMR-400 requires careful handling during installation. When bending the cable in multiple planes or around corners, installers should use a larger bend radius than the minimum to avoid stressing the internal structure.

Why Bend Radius Matters in Coaxial Cables

Exceeding the recommended minimum bend radius can lead to several serious mechanical and electrical issues, some of which may not be immediately visible.

1. Physical Damage

Over-bending can permanently damage the cable’s internal structure, including:

- Kinking or crushing of the outer conductor

- Deformation of the dielectric insulator

- Damage to the inner conductor

These deformations are often not visible from the outside, making them difficult to diagnose once installed.

2. Impedance Mismatch

Coaxial cables are engineered to maintain a specific characteristic impedance, typically 50 ohms for RF and antenna applications.

Sharp bends can distort the cable geometry, causing impedance, mismatches that lead to:

- Signal reflections

- Reduced power transfer

- Increased VSWR (Voltage Standing Wave Ratio)

3. Increased signal loss (attenuation)

When a cable is bent beyond its limits:

- The signal path may be altered

- Micro-deformations can increase resistance

- RF energy loss increases

This results in higher attenuation, reduced range, and poorer overall system performance.

4. Reduced Shielding Effectiveness

The shielding in coaxial cables protects against electromagnetic interference (EMI) and external noise.

Over-bending can:

- Separate or deform the shield

- Create gaps that allow EMI intrusion

- Increase susceptibility to noise and interference

This is especially problematic in industrial, cellular, and high-frequency environments.

5. Reduced Cable Lifespan

Repeated bending or maintaining a cable in an over-bent position can lead to:

- Metal fatigue in conductors

- Shield breakdown

- Premature cable failure

Even if the cable functions initially, its long-term reliability is compromised.

6. Electrical Short or Open Circuit

In extreme cases, severe over-bending can cause:

- Inner conductor contact with the shield (short circuit)

- Broken conductors (open circuit)

Either condition results in complete signal failure.

To avoid these issues, it's important to adhere to the above specifications for bend radius and handle coaxial cables with care during installation and maintenance.

Best Practices for Installing LMR Coaxial Cables

To maximize performance and longevity:

- Always follow the manufacturer’s minimum bend radius specifications

- Avoid sharp corners and tight loops

- Use cable clamps, guides, or strain reliefs

- Increase bend radius when routing in multiple planes

- Never force a cable into position

- Avoid repeated bending during maintenance

For outdoor installations, also consider temperature changes, as cold weather can reduce cable flexibility.

Conclusion

Understanding the bend radius of LMR-100, LMR-200, and LMR-400 coaxial cables is essential for proper RF system design and installation. While smaller cables offer greater flexibility, larger cables like LMR-400 deliver superior signal performance at the cost of rigidity.

Respecting minimum bend radius specifications helps prevent physical damage, signal loss, impedance issues, and premature failure—ensuring reliable, long-term performance in wireless and antenna applications.

When in doubt, use a larger bend radius than the minimum, and handle coaxial cables with care during installation and maintenance.

FAQs

What is the minimum bend radius of LMR-100, LMR-200, and LMR-400 coaxial cables?

The minimum bend radius depends on the cable size and construction:

- LMR-100: 0.25 inches (6.4 mm)

- LMR-200: 0.5 inches (12.7 mm)

- LMR-400: 1 inch (25.4 mm) when bending in a single plane

When bending LMR-400 in multiple planes or around tight corners, a larger bend radius is recommended to prevent damage and performance degradation.

Why is bend radius important for coaxial cable performance?

Bend radius is critical because bending a coaxial cable too tightly can damage its internal structure and alter its electrical characteristics. Exceeding the recommended bend radius can cause impedance mismatch, increased signal loss (attenuation), reduced shielding effectiveness, and shortened cable lifespan, all of which negatively impact RF system performance.

What happens if a coaxial cable is bent beyond its minimum bend radius?

Over-bending a coaxial cable can lead to both mechanical and electrical failures, including:

- Kinking or crushing of the cable

- Deformation of the dielectric or conductors

- Increased signal attenuation

- Impedance mismatches and higher VSWR

- Greater susceptibility to electromagnetic interference (EMI)

- In extreme cases, electrical shorts or open circuits

Some of these issues may not be visible externally but can still cause performance problems.

Is LMR-100 more flexible than LMR-200 and LMR-400?

Yes. LMR-100 is the most flexible of the three cables due to its small diameter. It is well suited for tight spaces, short antenna pigtails, and compact RF devices. However, despite its flexibility, repeated sharp bends should still be avoided to prevent long-term fatigue and damage.

Can LMR-400 be bent around corners during installation?

LMR-400 can be bent around corners, but it requires careful handling. Because it is thicker and more rigid, installers should:

- Maintain at least a 1-inch bend radius in a single plane

- Use a larger radius when bending in multiple planes

- Avoid sharp corners and forced bends

Using cable guides or gradual curves helps protect the cable and maintain optimal RF performance.

What are the best practices for installing coaxial cables to avoid bend radius issues?

To ensure long-term reliability and performance:

- Always follow manufacturer bend radius specifications

- Avoid tight loops and sharp corners

- Use strain reliefs, clamps, or cable guides

- Increase bend radius for multi-plane routing

- Do not force cables into position

- Minimize repeated bending during maintenance

- Consider temperature effects, especially in outdoor installations

Following these best practices helps prevent physical damage, signal loss, and premature cable failure.