Antenna Connectors Weatherproofing

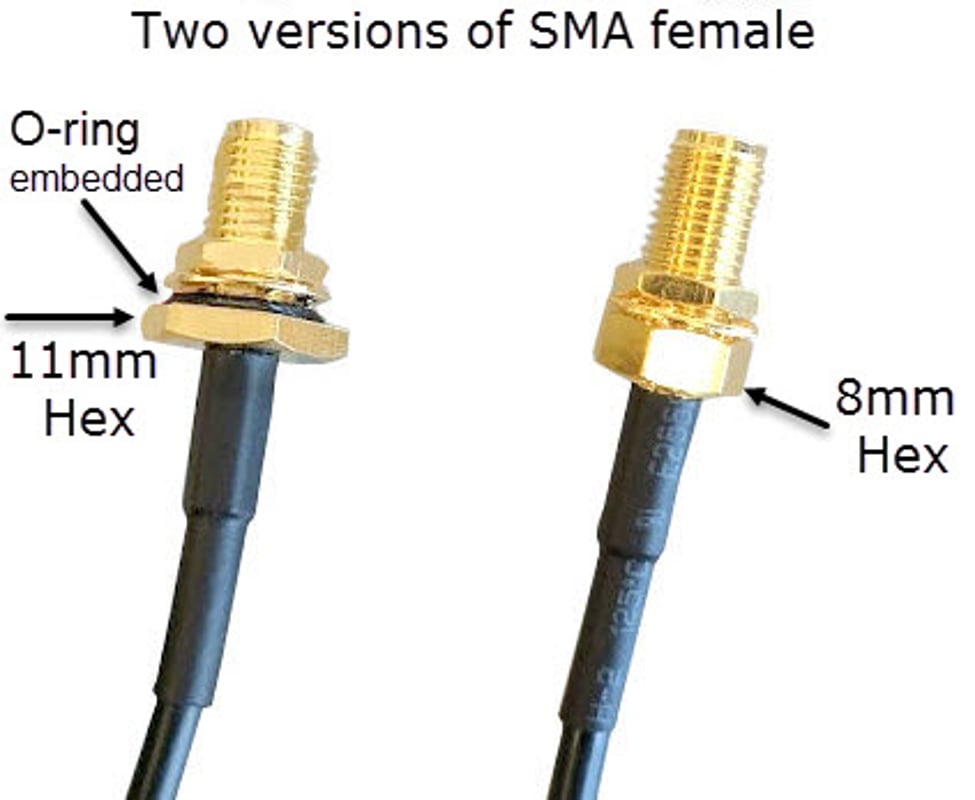

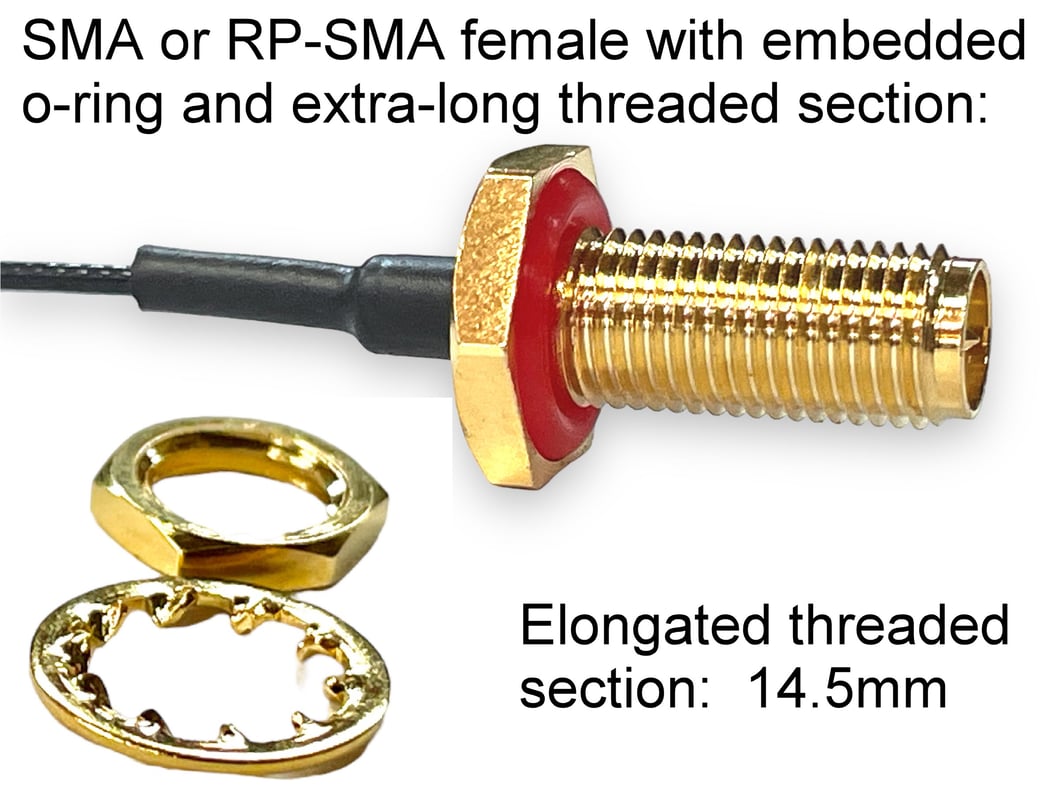

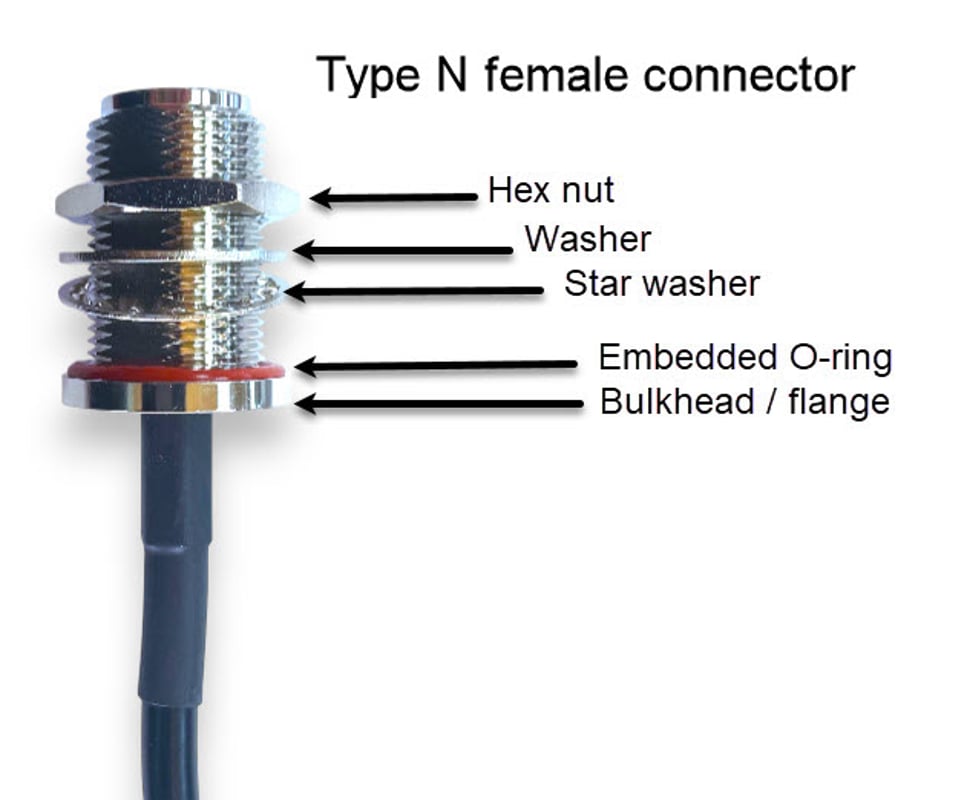

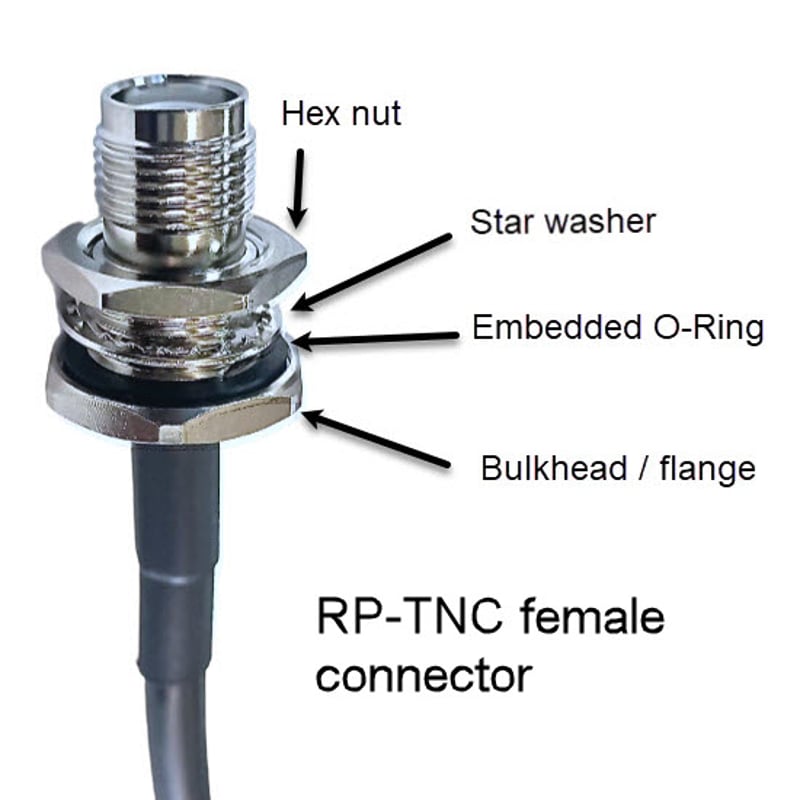

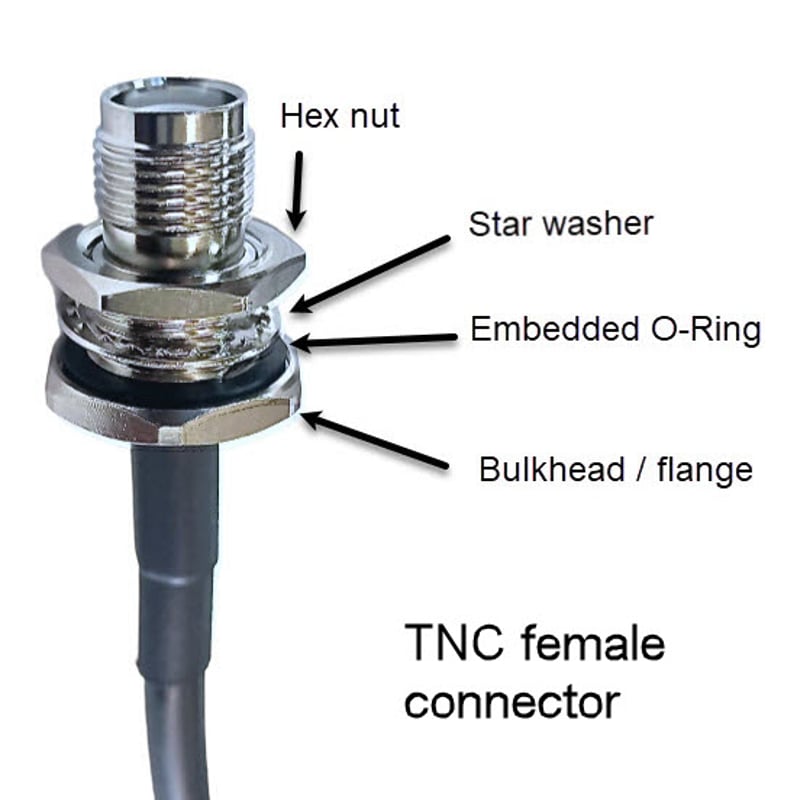

The first row of the gallery below shows various versions of SMA and RP-SMA connectors and how they can be weatherproofed with embedded o-rings. Type-N and TNC / RP-TNC are also below in the gallery.

|

|

|

|

|

|

|

|

|

Antenna Connectors Weatherproofing:

Data Alliance can provide a custom IP67 solution for your waterproofing / weatherproofing challenge.

Composition of Brass in Antenna Cable Connectors / Rustproofing

- Brass is an alloy composed of zinc and copper. The ratio of copper and zinc can be varied to produce versions of brass with different electrical, mechanical and chemical properties.

- Generally, a high copper content in brass increases its thermal and electrical conductivity. The copper is easily oxidized on the surface, creating a protective copper oxide layer (patina) that prevents further corrosion and rust. Typical electrical brass contains 70% copper that gives it a conductivity of 28%.

- Zinc is responsible for the hardness of brass. Zinc is cheaper but less conductive than copper, increasing its ratio in brass lowers the alloy’s production cost. Zinc is also fairly resistant to rust and corrosion.

- Brass manufacturers have to balance production cost with mechanical and conductivity performance of the alloy for different applications by carefully adjusting the percentages of copper and zinc.

RoHS standards allow the addition of small quantities of lead up to 4% to improve machinability and resistance to corrosion. Leaded brass is used for general purpose mechanically screwing components. However, Data Alliance's brass antenna cable connectors and adapters contain less than 1% lead.

Brass is a binary non-ferrous metal alloy, with more than 60 classified varieties of brass (based on composition), with different properties for specific applications. Brass is easily workable and resistant to sparking and wear. Its aesthetic properties, machinability, and durability in extreme environments make the alloy favored for low friction, ornamental and highly malleable applications. Brass is 23% to 44% (depending on the copper to zinc ratio) as conductive as pure copper making it a fair candidate for electrical applications.

Small quantities of other materials such as tin, arsenic, aluminum, and nickel are added to the alloy to increase corrosion resistance and alter mechanical properties.

Weatherproofing for Antenna Connectors

The rapid expansion of wireless networking for industry, business, and consumer use has demanded infrastructure and components that can withstand the continual challenge of harsh outdoor environments.

Antenna connectors or coaxial connectors are critical components for both antennas and their downstream radio frequency circuits and devices. Radiofrequency connectors provide a structurally and electrically matched conduit for the transmission of radio frequency signals with attenuation and interference kept to a minimum.

Why weatherproofing for antenna connectors is important

Antennas may be installed outdoors long-term for applications as diverse as supporting a cellular signal booster or ham radio. The exposure of precision RF connectors to outdoor environmental conditions can lead to not only damage and deterioration in the function of the connectors but also the performance of the radio frequency circuits and devices they are part of. Exposure prematurely ages the connectors, causing them to derangement from their specified electrical and structural characteristics. Key causes of weathering of outdoor antenna connectors include:

- Corrosion is the gradual breakdown of metals as they react with oxygen, moisture and chemicals, and particulates in the air. Any metal surfaces on the connector (even those that are plated) are vulnerable to the effects of corrosion which can impair their mating and cause electrical changes including, leakage currents, dielectric changes, and shorts.

- Windblown dust can settle on connector surfaces and create a build-up or patina that leads to the tarnishing of the plating and may progress to corrosion quickly if conditions are humid. Dust is continually present in the atmosphere and can become ingrained in connector threads, which may affect their coupling.

- Solar radiation causes heating of components like RF connectors as well as causing photodegradation due to UV exposure, especially where plastic or rubber parts are present.

- Moisture not only leads to corrosion but also can cause instant electrical damage, including short-circuiting if it can get into the connector interface. Humidity increases the risk of corrosion. The metal surfaces of the connectors can also be affected by runoff from cables or condensation as they cool.

- Temperature extremes can affect the plastic dielectric within the connector. Sequential shrinkage and expansion of the insulator as the temperature changes will lead to dielectric losses and leakage currents.

Weatherproofing is therefore essential for providing competent protection for antenna connectors, which in-turn preserves their function and prevents costly network downtime and equipment repairs.

Antenna connectors used for outdoor installations

There are several cost-effective solutions available for weatherproofing the leading types of coaxial connectors that are commonly used outdoors including:

- Sub Miniature version A (SMA) connectors are a 50 Ohm impedance sub-miniature threaded connector that is usually made from machined and plated brass or steel. It consists of a male connector that carried an inner pin conductor and internal threads and a female SMA connector that consists of a threaded barrel and has an internal receptacle that receives the male pin. It is connected by screw coupling and tightened via a hex nut carried on the male connector. It typically can support frequencies between DC and 18 GHz.

- Reverse-polarity SMA (RP-SMA) connectors are a variant of the SMA connector described above. They are structurally identical to standard SMA connectors and have the same coupling and electrical profile but have a reversal of the inner mating interface. The male RP-SMA connector carries the receptacle and the female RP-SMA connector has a pin.

- Type-N or N connectors are a larger and more rugged threaded connector that is known for its performance in outdoor installations. Its impedance is 50 Ohms and it can transmit a maximum frequency of 18 GHz. The male connector has internal threading and a pin, and the female connector has external threading and an inner receptacle.

These high-specification RF connectors are used in a range of outdoor microwave frequency applications including telecommunications, Satcom, cellular networking, wireless networking, testing and measurement, and instrumentation. They are also frequently encountered as antenna connectors and are often integral to their mounting.

Diverse solutions for protecting antenna connectors

[A] O rings and gasketsare a simple but effective way of weatherproofing antenna connectors. They are rubber, silicone, or silicone rubber rings, with a circular cross-section, that can be used with bulkhead connectors and their nuts to fully seal them from moisture ingress. Silicone rubber gaskets can sit on either end of the threaded body of the bulkhead connector and are compressed to a watertight seal when the nut or washer is tightened down. As the material of the gasket is distensible, when it is compressed by two mating surfaces it will fill up any spaces and crevices where dust and dirt could enter. By using a rubber O-ring seal, a bulkhead or standard connector can be made fully waterproof (IP68 equivalent).

[B] Cable glandsare used to protect antenna connectors and cabling that exits the knockout of an electronic enclosure. These are quick connect bulkhead-style conduits that fully seal the connector and its cable from the ingress of moisture and dust. Glands also prevent damage to cable assemblies and connectors by properly routing them and minimizing excessive bending and strain, especially where a straight geometry connector is attached to a cable. Glands consist of a sealed threaded body that is passed through the enclosure wall. It is held in place by a lock nut, which tightens down against the enclosure wall, and a sealing nut that contains an inner waterproof seal. The gland is disassembled and the cable and connector fed through the sealed body and then reassembled securely. Glands should be selected to match the enclosure material (plastic or metal) as well as the enclosures ingress protection, NEMA, or Underwriters Laboratories rating.

[C] Waterproof seal tapeconsists of a highly moldable mastic tape that has a long history of use for sealing outdoor antenna connectors. The black tape can be stretched and wrapped around mated connectors. When activated by using it becomes pliable and tarry, and can be worked into a seal that prevents contaminants from accessing the connector and insulates connectors from sunlight and temperature fluctuations. Even though coax sealant tape has a good grip on metal and plastic it is readily removed by cutting it open with a sharp blade and peeling it off.

[C] Silicone Greaseis made by thickening silicone oil with amorphous fumed silica. The resultant dielectric grease is available in a range of thicknesses and can be spread over RF connectors and cables that will be installed outdoors. The liberal application provided a waterproof barrier that prevents both moisture and dust from getting to the inner mating interface of the connector and causing corrosion. It also prevents particulates from becoming lodged in the connector threads. Silicone grease is

an effective electrical insulator and will minimize leakage currents and EMI across the connector.

[D] Dust caps or 50 Ohm terminatorsare used for protecting the unmated ends of antenna connectors, panel-mounted radio frequency connectors, or cables. This keeps the connector ends free from contaminants and moisture that can cause corrosion and impair the performance of the connector. Using a metal or plastic dust cover also minimizes the leakage of radio frequency energy via the uncapped connector which can be a source of electromagnetic interference (EMI) and high static charge.

Coaxial connector caps are often made to military specification and carry an insulator inner conductor. They can be secured to the assembly by using a chain or cord that prevents them from getting lost.

[E] Flat coax cable: Flat coaxial cable couplers, window entry cables, or window jumpers are a unique solution for bringing connectivity from an outside antenna indoors, via the window rather than drilling masonry to bring in antenna Cables from outside. A conventional coax cable passed through a window would require the window to remain open or risk crushing or damaging the cable. The flat coaxial coupler passes signal between the two standard radio frequency connectors at either end of its flattened length. Its thickness is usually no more than 4.5mm (0.18 inches). Despite their unusual shape, they have a remarkably low level of signal loss. Some couplers carry an adhesive strip so that the cable coupler can be fixed to the window frame or a bulkhead connector for secure mounting if required. The window jumpers usually have a length of mini-coax running down the mid-length of the cable, supported by copper beads that protect the cable from the effect of pressure or slam impacts when the window is closed.

RoHS compliant weatherproof bulkhead antenna connectors

Bulkhead radio frequency connectors facilitate secure, weatherproof mounting of high specification connector to panels enclosure walls and antenna mounts. These threaded panel-mounts usually carry female connectors for the leading connector type N-type female, SMA, and RP-SMA. This is because the narrower threaded barrel of the female connector can pass through the metal hole more readily and have either the counterpart male connector or a fastening nut screw down onto both ends easily. The connector should deliver comparable structural and electrical performance to the standard antenna connector. Bulkhead connectors are simple and easy to install and make an inexpensive mounting option that is easily replaced if the connector becomes worn.

Frequently asked questions

Which other accessories are useful for protecting outdoor wireless networking installations?

Wireless networking equipment including antennas, routers, and access points can have enhanced protection from outdoor exposure by housing them inside an electronics enclosure. These durable weatherproof lidded boxes protect sensitive electronics and keep them in a dry temperature stable environment that prevents the ingress of moisture, dust, and dirt. Many enclosure designs are specifically for wireless networking equipment the enclosures are typically made from robust thermoplastics like polycarbonate, PVC, and ABS. Plastics are preferable for enclosures for antennas as they are freely permeated by radio frequency signals, unlike metal.

How do I mount an antenna outdoors?

Always fully read and familiarize yourself with the manufacturer’s instructions before starting. Mounting a weatherproof antenna outdoors should only be undertaken if you are competent to do so. Abide by national, state, and local electrical guidelines and codes. Do not attempt to mount an antenna in wet or stormy conditions or where there are high winds.

- If wall-mounting:

An outdoor antenna can be securely mounted using an L-mount or bracket. This galvanized metal bracket can be secured to the external wall using suitable screws and masonry plugs. The female-to-female bulkhead antenna connector can be passed through an appropriately sized hole on the mount. Once the bulkhead is installed the antenna cable is attached first with a dust cover of the appropriate type on the end of the bulkhead that will attach to the antenna, to help dissipate any damaging static build-up (which can create a high static charge) in the cable before the antenna is attached. The antenna can then be attached to its bulkhead connector and tighten to the appropriate level of torque.

- If pole-mounted:

An L-mount can still be used with the bulkhead connector, but instead of attachment to the wall, U-bolts can be passed, allowing the mount to be securely tightened to a pole.

Avoid over-tightening cables and antenna on the bulkhead connector as this can cause damage.

Coax tape and silicone grease can be used to protect the bulkhead and antenna connectors.

In conclusion

By using our diverse range of weatherproofing products you have a range of strategies at your disposal for the secure and weatherproof installation of antenna connectors. Protecting antenna connectors with cost-effective solutions like dust caps, dielectric grease, and cable glans is a prudent investment for ensuring that an outdoor networking installation should perform as it should long-term.

LEARN MORE: